WEMA SI solves simple and complex internal grinding tasks quickly and efficiently. A multi-settable internal round table and a work headstock are guided to the μm. As with all our machines, SI is scalable and is adapted to your needs through a specific mounting for the greatest machining efficiency.

Since time is always important, we rely on our optimised procedures: Our powerful drives ensure a quick availability with additional work and peripheral modules reducing costly non-productive times. You stand to benefit from this through reduced cycle times, greater throughput and more satisfied customers.

Key Facts

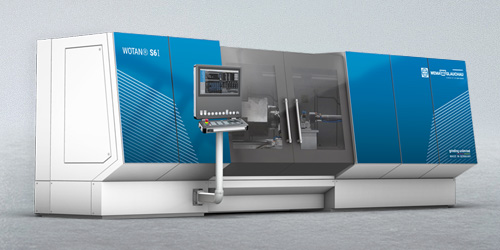

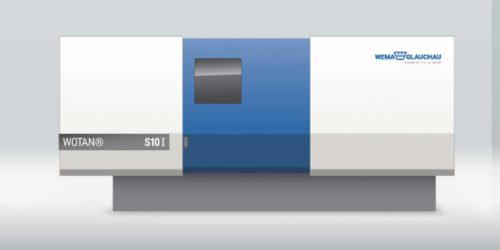

- Available in 3 different series (S3I, S6I, S10I)

- Machining of chuck and shaft-shaped parts (steady-rest guided)

- Internal cylinder/ cone, internal polygons, internal screw threads and more

- Up to 4 applicable internal grinding tools (fixed on B2 axis)

- High rigidity through the use of cast beds / Hydropol beds

- External machining of the components possible

For #cylinder #taper #polygon #thread #eccentric

400 mm

650 / 820 mm

1,200 mm

450 mm

800 / 1,200 / 1,800 mm

700 mm

400 kg

650/1,300 kg

1,000 kg

350 mm

620 mm

850 mm

400 mm

650/1,200 mm

500 mm

Axis speed

0–15.000 mm/min

Tool round table

Direct drive/ Externally driven with 0.00005°

With up to 4 tool positions and a tailstock

Workpiece mandrel drive

Rolling bearing, belt drive without measuring system

Rolling bearing, direct drive with measuring system as C‑axis

Hydrostatic bearing, direct drive with measuring system as C‑axis

Rolling bearing, belt drive

Options

- Revolver headstock with up to 4 internal grinding mandrels

- Optional external machining and facing operations

- Workpiece headstock with B axis

- Hydrostatic workpiece mandrel

- Probe for zero point measurement

- Fixed and/or powered dressing tools

- Tool change system

- Pre‑, in- and post-processing measuring systems